In the ever-evolving landscape of industrial materials, grounded calcium carbonate (GCC) plays a pivotal role. From plastics and paints to paper and pharmaceuticals, this versatile mineral finds use in almost every major manufacturing sector. As demand rises, so does the need for reliable sourcing. That’s where a trusted Calcium carbonate supplier comes into play, especially those offering consistent quality and large-scale delivery across India.

Whether you’re in construction, paints, rubber, or paper manufacturing, choosing the right Grounded calcium carbonate suppliers in India can significantly affect your product quality, cost-efficiency, and business scalability.

Let’s dive into everything you need to know about GCC, its applications, benefits, and how to choose the best Grounded calcium carbonate manufacturers in India for your business needs.

What is Grounded Calcium Carbonate (GCC)?

Grounded Calcium Carbonate (GCC) is manufactured by crushing and grinding naturally occurring limestone (calcium carbonate rock) into a fine powder. Unlike precipitated calcium carbonate, which is chemically processed, GCC is obtained directly from quarry-sourced minerals and retains a more natural crystalline structure.

It typically appears as a white, odorless powder and is valued for its high brightness, low oil absorption, and cost-effectiveness.

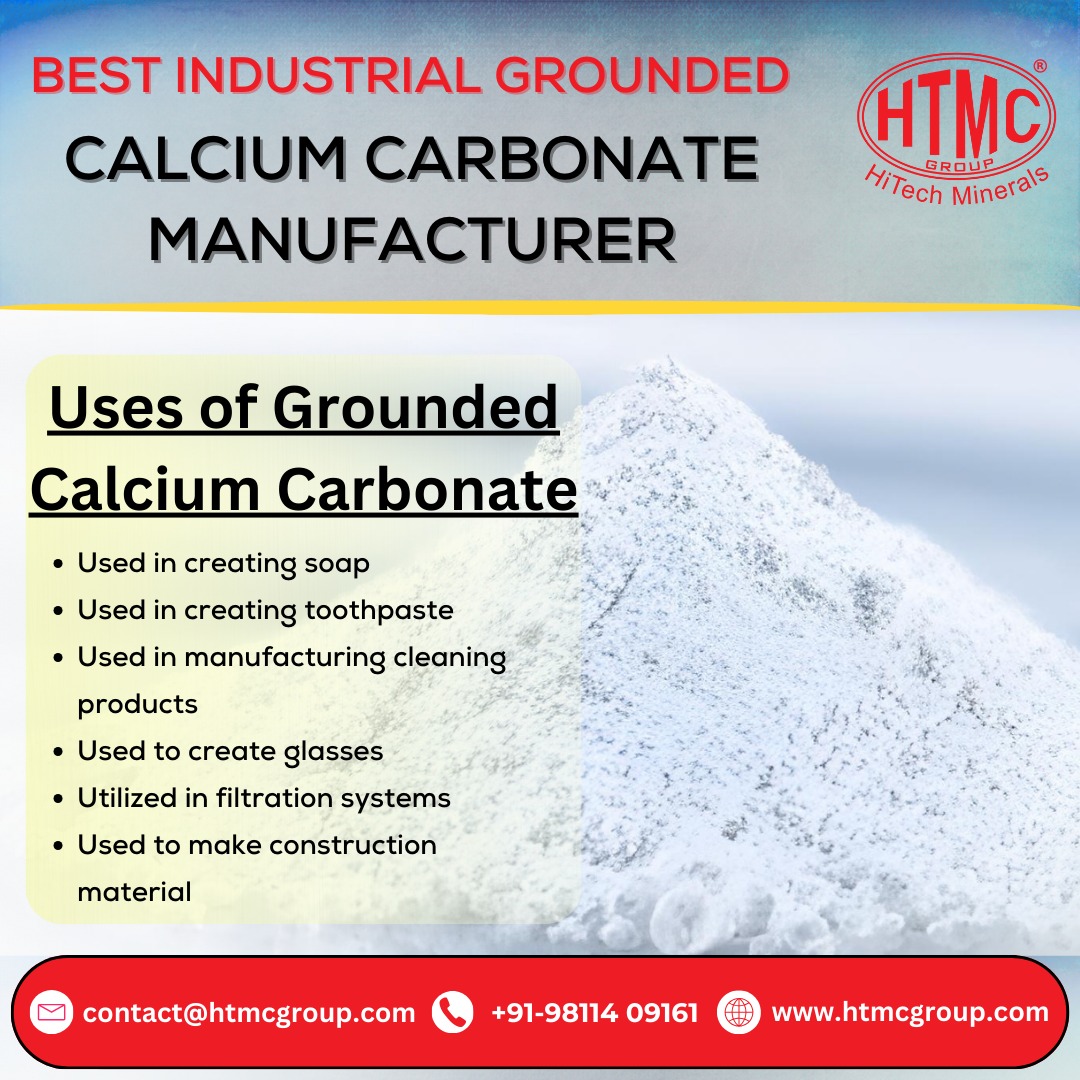

Major Industrial Applications of Grounded Calcium Carbonate

The unique physical and chemical properties of GCC make it indispensable in numerous sectors. Here are some key applications:

- Paper Industry

GCC is widely used as a filler and coating pigment. It enhances brightness, opacity, and surface smoothness while reducing manufacturing costs.

- Paints and Coatings

It serves as an extender in paints and coatings, helping to control gloss, improve weather resistance, and provide smooth texture.

- Plastics and Polymers

GCC adds strength, rigidity, and dimensional stability to plastic products. It also improves heat resistance and reduces production cost.

- Rubber Industry

Used as a reinforcing filler in rubber manufacturing, it improves elasticity, reduces shrinkage, and enhances the finish.

- Pharmaceutical and Food Applications

In its highly purified form, calcium carbonate is used as a dietary calcium supplement and as an antacid.

- Construction Sector

In concrete and cement manufacturing, GCC improves the durability and strength of the final product.

Clearly, having access to a dependable Calcium carbonate supplier can drive both quality and cost efficiency across operations.

Advantages of Using Grounded Calcium Carbonate

When sourced from a quality manufacturer, GCC brings multiple advantages:

- Cost-effective: Acts as a filler or extender, reducing overall material costs

- Eco-friendly: Non-toxic and naturally occurring, making it a sustainable choice

- High compatibility: Blends well with resins, binders, and polymers

- Consistency: Maintains stability in physical properties across production batches

- Versatility: Can be customized to different micron sizes for specific applications

Why Choose Grounded Calcium Carbonate from Indian Manufacturers?

India is home to rich limestone reserves and a well-developed industrial base, making it a hub for calcium carbonate production. Here’s why Grounded calcium carbonate manufacturers in India are gaining global recognition:

- Abundant Raw Material: Rich limestone belts across Rajasthan, Gujarat, and Madhya Pradesh ensure continuous raw material supply.

- Advanced Manufacturing: Adoption of cutting-edge grinding and classification equipment ensures uniformity in particle size and quality.

- Cost Efficiency: Competitive pricing without compromising on quality

- Eco-Conscious Production: Increasing focus on green manufacturing practices

- Global Export Standards: Many Indian manufacturers adhere to international quality certifications such as ISO and GMP

Choosing the Right Grounded Calcium Carbonate Supplier

Not all suppliers are created equal. Here are some factors to consider when selecting the best Grounded calcium carbonate suppliers in India:

- Product Range and Grades

A good supplier should offer a variety of particle sizes and grades, from coarse to ultra-fine GCC. This flexibility allows customization based on industry-specific needs.

- Consistency and Purity

Check for consistency in brightness, particle size distribution, and chemical purity. Impurities in calcium carbonate can affect the end product’s quality.

- Infrastructure

Well-equipped processing units with automated systems for drying, grinding, and micronizing are essential for consistent product quality.

- Technical Support

A supplier that offers technical assistance for product integration and application development adds tremendous value.

- Logistics and Delivery

Timely delivery and proper packaging are crucial, especially for high-volume users. Choose a supplier with a strong logistics network.

Meet a Trusted Name: HTMC Group

One of the leading names in the Indian calcium carbonate industry is the HTMC Group. With decades of experience and state-of-the-art manufacturing units, HTMC offers reliable, high-purity grounded calcium carbonate tailored to the needs of diverse industries.

Their product portfolio caters to:

- Paper & Printing

- Plastics & PVC

- Paints & Coatings

- Rubber & Tyre Industry

- Adhesives & Sealants

HTMC ensures:

- Micron-level precision in particle size

- High brightness and whiteness

- Stable pH and low moisture content

- ISO-certified processes and eco-friendly practices

Whether you’re a domestic manufacturer or an international buyer, HTMC stands out as a trusted Calcium carbonate supplier with a proven track record.

Conclusion

In today’s competitive industrial landscape, quality and consistency matter more than ever. Grounded calcium carbonate continues to be a foundational ingredient across sectors, offering performance enhancement and cost savings. Choosing the right Grounded calcium carbonate suppliers in India ensures that you stay ahead in terms of product quality, compliance, and customer satisfaction.