The embroidery industry is threading a new path—one that’s greener, cleaner, and kinder to the planet. As consumers and businesses alike demand eco-conscious alternatives, embroidery digitizing services are stepping up, transforming how designs are stitched without compromising the Earth’s fabric. From recycled threads to zero-waste workflows, sustainability is no longer a buzzword; it’s a needle moving the entire industry forward. Let’s unravel how modern embroidery digitizing services are stitching sustainability into every loop and chain.

The Problem with Traditional Embroidery

Traditional embroidery has a dirty little secret: it’s resource-heavy. Conventional threads often rely on petroleum-based polyester, stabilizers contribute to landfill waste, and energy-guzzling machines leave a carbon footprint. A single misdigitized design can waste yards of thread and fabric, while outdated practices prioritize speed over sustainability. For small brands and large corporations alike, these inefficiencies clash with today’s eco-conscious values. Enter Eco-Stitch—a movement redefining embroidery digitizing through innovation, ethics, and smarter tech.

Recycled Threads: Turning Waste into Wearable Art

The backbone of any embroidery project is thread, but not all threads are created equal. Leading eco-conscious digitizers now partner with suppliers like Madeira’s EcoLine or Aurifil’s Sustainable Collection, which craft threads from recycled plastic bottles, organic cotton, or even discarded fishing nets. These materials slash reliance on virgin polyester, reducing both plastic pollution and carbon emissions.

Take OceanStitch, a California-based service that uses 100% ocean plastic-derived threads. Their digitizers optimize designs to minimize thread usage, ensuring each spool goes further. The result? A hat embroidered with their thread removes the equivalent of three plastic bottles from marine ecosystems.

Waste-Not Digitizing: Smarter Files, Less Trash

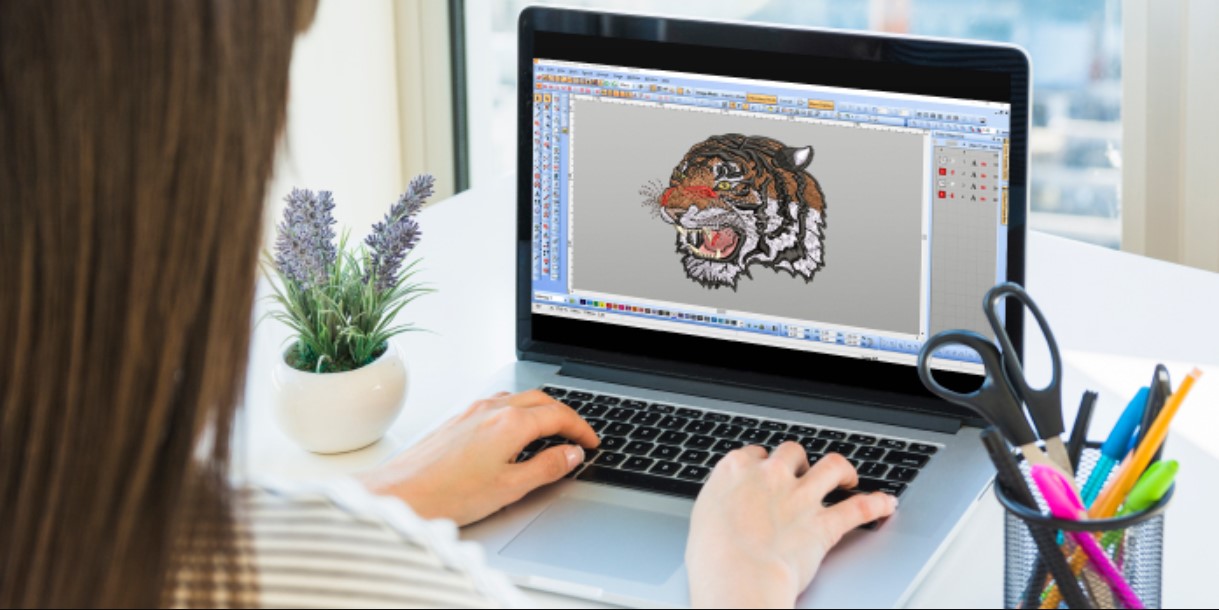

Digitizing isn’t just about translating art—it’s about precision. Advanced software like Wilcom Hatch now includes AI tools that predict the most efficient stitch paths, reducing thread waste by up to 30%. For example, a logo that once required 5,000 stitches might now use 3,500 without sacrificing quality. Services like GreenStitch Pro take it further by analyzing fabric types to recommend stabilizers that dissolve harmlessly or biodegrade, eliminating the mountain of plastic-backed waste common in traditional setups.

But the real game-changer? Closed-loop systems. Companies like EcoEmbroider recycle thread scraps and fabric offcuts into new materials, partnering with local artists to turn waste into wall art or packaging. It’s a full-circle approach that’s as creative as it is sustainable.

Energy Efficiency: Stitching with Solar & Smarter Tech

Embroidery machines aren’t known for being energy sippers—industrial models can guzzle as much power as a small household. Forward-thinking digitizers are tackling this by:

- Switching to solar-powered workshops (like SunStitch Studios in Arizona).

- Using ENERGY STAR-certified machines that cut energy use by 40%.

- Offering “slow stitching” options, prioritizing quality over speed to reduce machine runtime.

Even small changes add up. ThreadForward, a UK-based service, reduced its carbon footprint by 25% simply by digitizing designs to require fewer color changes, minimizing machine stops and starts.

The Rise of Eco-Certifications & Transparency

Greenwashing is rampant, but certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX help brands identify legit eco-digitizers. These certifications ensure threads are toxin-free, labor practices are ethical, and waste management meets strict standards.

Transparency is also key. Services like EcoDigitize provide clients with a “sustainability report” for each project, detailing resources saved, carbon offset, and even the recycled content of threads. It’s a level of accountability that builds trust and aligns with the values of eco-conscious consumers.

Case Study: How a Fashion Brand Went Green

Consider Wildflower Apparel, a boutique activewear brand. They switched to a sustainable digitizer to embroider their yoga leggings, opting for organic cotton threads and compostable stabilizers. The digitizer optimized their lotus logo to use 20% less thread while maintaining detail. The result? A 50% reduction in material waste and a marketing boost—their “Eco-Lotus” line sold out in 48 hours, appealing to sustainability-minded yogis.

Debunking Myths: Cost, Quality, and Compromise

Skeptics argue that sustainable digitizing is pricier or lower quality. The truth? While eco-threads can cost 10–15% more upfront, waste reduction and energy savings often balance the scales. As for quality, recycled threads now rival conventional ones in durability and color vibrancy. Brands like Patagonia and Eileen Fisher use them in high-end collections without compromise.

How to Choose an Eco-Conscious Digitizer

Ready to green your embroidery? Vet services with these questions:

- Do they use certified recycled/organic threads?

- What waste management systems do they have?

- Can they provide energy usage stats or carbon offsets?

- Do they avoid toxic stabilizers or adhesives?

Reputable providers will gladly share their practices—no stitching around the truth.

The Future: Where Tech Meets Sustainability

The next wave of eco-stitching is already here. Startups are experimenting with algae-based threads that decompose harmlessly, while AR tools let designers visualize stitches digitally, slashing physical prototypes. Blockchain is even entering the scene, tracing threads from recycled source to finished product, ensuring authenticity.

Stitch with Purpose

Eco-Stitch isn’t a trend—it’s a revolution. By choosing sustainable digitizing, brands don’t just reduce their environmental impact; they weave ethics into their identity. Every thread becomes a statement, every design a testament to innovation. Whether you’re embroidering 10 hats or 10,000 uniforms, the future of embroidery is green, clean, and brilliantly stitched.

So, next time you digitize a design, ask: Is this thread part of the problem—or the solution? The answer could redefine your brand’s legacy.