How to Ensure Takeout Box Quality?

- Book My Author

- Business

- 2025-09-22 12:52:24

- 896K

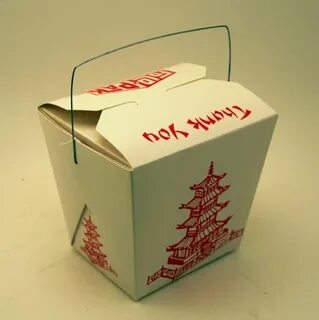

The use of custom take-out boxes has become a commodity in the modern-day packaging of food items and presents convenience, portability, and branding prospects to restaurants and food sellers. As the number of persons expecting quality takeout services increases, packaging is very important in guaranteeing that the food is fresh and undamaged and looks visually attractive.

Not every box is the same, however. Companies have to pay attention to the quality of materials, strength of the structure, design accuracy, and legal correspondence to achieve high standards and surpass customer expectations. In this article, we will look at what it takes in order to maintain quality in the process of producing custom takeout boxes, including the material used, finishing touches, and so on.

Select a Proper Material

The first thing in making a certain packaging durable and safe is the choice of the right material. The Kraft take-out boxes are the most common type, which are environmentally friendly and are made using recycled paperboard. They are tough and grease-proof in addition to being biodegradable, hence suitable for hot, greasy, or wet food stuff. Dishes that need extra protection can be made with coated paper or corrugated paper, where the paper is stronger and moisture resistant.

Apply Food-Safe Paintings

Paper take-out boxes UK are always preferable and should be kept in mind to keep the place hygienic and safe by using food-safe coated products. These linings avoid the soaking up of the oil or the moisture and preserve the quality of the temperature and integrity of the contents. All food packaging must be based on food-grade coatings certified by the FDA, with or without its approval, to avoid contamination and health requirements.

Correct Sizing

A snug-fitting box minimizes the possibility of spills, crush damage, and wastage. Tailor-made design will make food safe and presentable when being transported. To make Christmas take-out boxes both effective and satisfying to consumers, when the boxes are made to take account of special events or daily containers meant to hold different sizes of food without omitting the various types to suit various meals, they become more useful and likely to be preferred by the consumer.

Investment in Structural Integrity

The construction and box shape have a direct influence on strength and ease of use. The boxes typically used to package Chinese takeout are made in a way that the flaps are foldable, possibly with handles and bottoms secured. Tough corners, back-back sides, or lids that interlock enhance durability. Perform stackability, stability, and leak resistance tests on prototypes before large production runs.

Major in Print Quality

All the boxes should be imbued with your brand personality. Printed Chinese take-out boxes will assist you in expressing your professionalism, personal character, and detail. Good quality is signified by high resolution printing, uniform color schemes, and strong printing inks. Depending on the size of orders and complexity of design, digital, offs, et, or flexographic printing can be used.

Carry Out Frequent Quality Tests

To identify the problems early, it is recommended to develop a quality assurance process. Check every panel in a batch for being defective, including mismatched prints, folding at the wrong places, or poor gluing. Test the consistency of production by assessing through visual inspection, drop tests, and moisture resistance tests. Regular quality inspections will eliminate the production of faulty products, which can destroy your brand image.

Collaborate with trusted Suppliers.

To be consistent with quality control and more accountable, it is always good to have partners with experienced manufacturers in Custom boxes wholesale. One should look at a good supplier since it offers sample testing, certifications, and material and design flexibility. Transparency between the production process and the delivery process is very important in ensuring that targets and standards are achieved.

Special Occasions Adaptation

Event packaging or holiday packaging should be devoted to preserving the same quality as daily packaging. Christmas take-out boxes, as an example, should be cheerful or festive, but also able to carry something without any kind of leakage or damage. Seasonal boxes usually contain specialty prints or finishes, be sure these extras do not impair the strength or food safety.

Conclusion

To deliver the value, packaging needs to have both a form and functionality. The most acceptable part of takeout packaging is sustainability through custom takeout boxes, right up to custom food boxes to establish brand identity and quality assurance. All these factors, such as material, design, printing, and construction, have to be in sync with each other in order to equip a box that responds well to pressure and bears a positive image of your business. The same has happened to me; with good production habits and trustful partners, I produce takeout packaging that consistently impresses customers and builds a good reputation for my brand.