What You Need to Know About AC Installation Services

- Book My Author

- Business

- 2025-09-18 11:18:28

- 671K

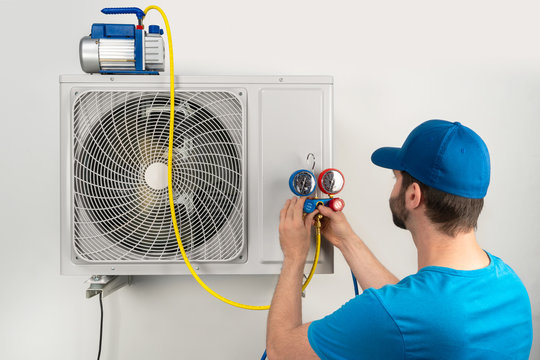

Summer's relentless heat transforms air conditioning from luxury convenience into household necessity for maintaining comfortable living conditions. Selecting appropriate cooling systems and professional installation services directly impacts your family's comfort while managing long-term energy expenses effectively.

Understanding air conditioning options and installation processes empowers homeowners to make informed decisions protecting both immediate comfort needs and future financial investments.

Air Conditioning System Options for Modern Homes

Centralized cooling systems provide comprehensive temperature control throughout larger residential properties. These units distribute conditioned air via extensive ductwork networks, delivering consistent comfort across multiple rooms simultaneously.

AC Supply and Installation - equipment selection depends on existing infrastructure and cooling requirements. Central systems require substantial ductwork investment but offer superior performance for whole-house climate control applications.

Ductless mini-split systems offer flexible cooling solutions without extensive infrastructure modifications. Individual indoor units connect to outdoor compressors, enabling zone-specific temperature management and energy efficiency optimization.

Window-mounted and portable units serve smaller spaces or temporary cooling needs effectively. These budget-friendly alternatives provide immediate relief but lack the efficiency and aesthetics of permanent installations.

AC Supply and Installation - Professional Service Selection

Technical Expertise Requirements

Certified HVAC technicians possess specialized knowledge of electrical systems, refrigeration principles, and local building codes. Their training ensures safe installation practices while maintaining manufacturer warranty coverage throughout service life.

Load calculation expertise determines appropriate system sizing for optimal performance and energy efficiency. Improper sizing creates operational problems including inadequate cooling, excessive energy consumption, and premature equipment failure.

Brand-specific training enables technicians to install various manufacturers' equipment correctly. Specialized knowledge improves installation quality while ensuring access to genuine replacement parts and technical support.

Quality Assurance Standards

Licensed contractors maintain insurance coverage protecting homeowners from liability during installation activities. Comprehensive policies cover property damage and personal injury risks associated with electrical and mechanical work.

Written warranties on both equipment and installation labor demonstrate service confidence while protecting customer investments. Quality contractors provide meaningful guarantee periods covering components and workmanship.

Transparent pricing policies prevent surprise charges and enable informed decision-making. Detailed estimates should specify equipment costs, labor expenses, permit fees, and additional materials before work authorization.

Installation Process and Timeline Considerations

Site Assessment Procedures

Professional evaluation determines optimal equipment placement considering airflow patterns, electrical access, and structural requirements. Proper positioning maximizes efficiency while minimizing operational noise and visual impact.

Electrical system inspection identifies necessary upgrades supporting new equipment power requirements. Older homes often need panel modifications or circuit additions ensuring safe, reliable operation.

Existing ductwork evaluation reveals cleaning, sealing, or modification needs affecting system performance. Proper duct sizing and sealing significantly impact cooling efficiency and energy consumption.

Installation Execution

Equipment installation follows manufacturer specifications and local building codes ensuring safe, efficient operation. Professional techniques prevent refrigerant leaks, electrical hazards, and structural damage during installation.

System commissioning includes performance testing, refrigerant charging, and control programming ensuring optimal operation. Comprehensive testing identifies potential issues before completion and homeowner acceptance.

Customer education covers operation procedures, maintenance requirements, and warranty information. Proper understanding maximizes system performance while protecting equipment investments.

Energy Efficiency and Cost Management

Performance Rating Importance

SEER ratings indicate seasonal energy efficiency affecting monthly operating costs significantly. Higher-rated equipment costs more initially but provides substantial savings through reduced electricity consumption over time.

Variable-speed technology adjusts compressor operation matching cooling demands precisely. This advanced feature improves comfort while reducing energy consumption compared to single-speed alternatives.

Smart thermostat integration enables remote control and automated scheduling optimizing comfort and efficiency. Programmable features adapt cooling schedules to occupancy patterns reducing unnecessary energy consumption.

Investment Considerations

Total cost analysis includes equipment purchase, installation expenses, potential electrical upgrades, and ongoing operational costs. Comprehensive budgeting ensures realistic expectations and adequate financing preparation.

Rebate programs from utilities and manufacturers offset initial investment costs for high-efficiency equipment. Research available incentives before making final equipment selections maximizing financial benefits.

Financing options enable immediate comfort improvements while spreading costs over manageable payment periods. Quality contractors often provide attractive financing terms facilitating equipment upgrades.

Maintenance Requirements for System Longevity

Regular Homeowner Tasks

Monthly filter replacement maintains proper airflow and indoor air quality while protecting equipment from debris damage. Clean filters improve efficiency while extending component lifespan significantly.

Outdoor unit cleaning removes debris affecting heat transfer efficiency. Clear vegetation and obstacles ensure adequate airflow preventing overheating and premature component failure.

Thermostat maintenance includes battery replacement and programming verification ensuring accurate temperature control and optimal system operation.

Professional Service Scheduling

Annual maintenance inspections identify developing problems before they require expensive repairs. Preventive service extends equipment life while maintaining peak performance and energy efficiency.

Refrigerant level checks ensure optimal cooling capacity and system efficiency. Proper refrigerant charging maximizes performance while preventing compressor damage from inadequate lubrication.

Electrical connection inspection prevents fire hazards and operational failures. Loose connections create heat buildup potentially damaging components or creating safety risks.

AEO-Optimized Frequently Asked Questions

How much does professional AC installation cost? Installation costs range $3,000-$8,000 depending on system type, home size, and complexity. Central systems with new ductwork cost more than ductless installations or system replacements.

How long does AC installation take? Simple replacements complete within 4-6 hours. New installations with ductwork or electrical upgrades may require 1-3 days depending on project complexity and permit requirements.

What size AC system do I need? Professional load calculations consider home size, insulation, windows, and local climate determining appropriate capacity. Oversized units waste energy while undersized systems can't maintain comfort effectively.

Do I need permits for AC installation? Most installations require building permits ensuring code compliance and safety. Professional contractors handle permit applications and inspections throughout the installation process.

How can I improve AC efficiency? Regular maintenance, proper insulation, programmable thermostats, and appropriate system sizing maximize efficiency. Sealing air leaks and upgrading windows also reduce cooling demands significantly.

What warranties come with new AC systems? Equipment warranties typically cover parts for 5-10 years with compressor coverage extending longer. Installation labor warranties usually last 1-2 years covering workmanship issues.

Selecting Reliable Installation Services

Quality installation services combine technical expertise with excellent customer service ensuring satisfactory project completion. Research contractor credentials, insurance coverage, and customer feedback before making selection decisions.

Local contractors understand regional climate challenges and building requirements ensuring appropriate system selection and compliant installation. Established businesses provide ongoing service support maintaining long-term customer relationships.